Comprehensive Electronics Manufacturing Services

From design support to production, we provide one-stop solutions to ensure your products are exceptional.

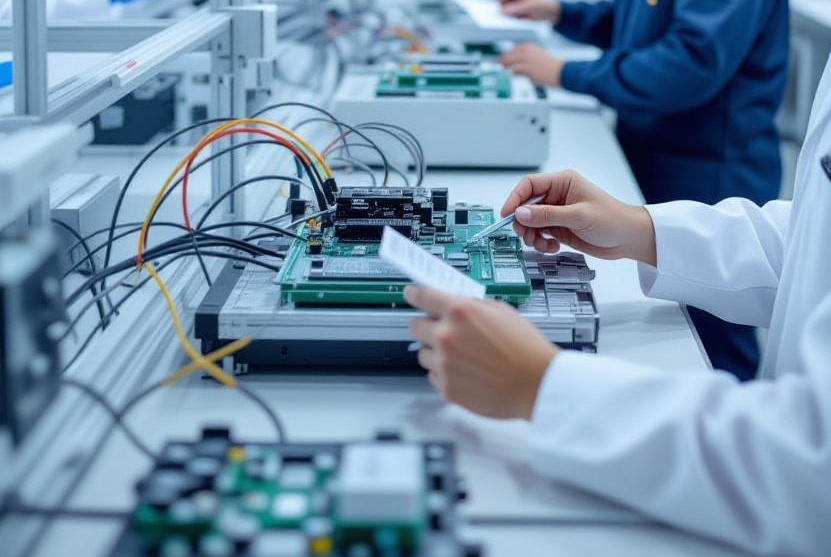

OEM Services

Angel Electronics provides comprehensive OEM (Original Equipment Manufacturing) services, covering the entire process from product design support and component procurement to final production and assembly. Our professional team will work closely with you to transform your concepts into high-quality physical products. The electronic products we manufacture include network communication electronics, computers and peripherals, industrial electronics, automotive electronics, optoelectronic products, consumer electronics, medical electronics, and commercial electronics.

- Design Support: Assist in optimizing product appearance and structural design.

- Component Procurement: Carefully select quality suppliers to ensure material quality and stable supply.

- Manufacturing & Assembly: High-performance production lines ensure on-time product delivery.

- Quality Testing: Strict quality control processes ensure every product meets high standards.

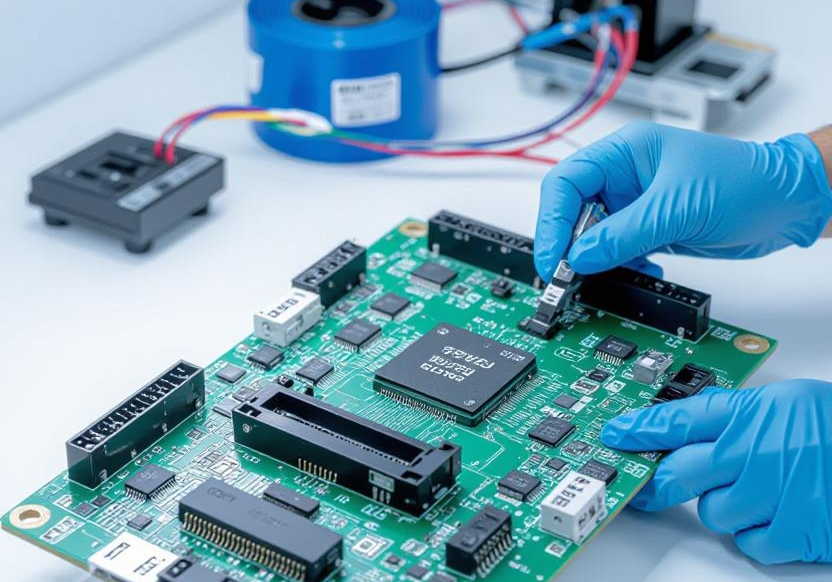

EMS Services

We specialize in Printed Circuit Board Assembly (PCBA) services. From Surface Mount Technology (SMT) to wave soldering, our advanced equipment and professional expertise ensure the highest assembly precision and reliability. Whether it's prototyping or mass production, we can provide customized solutions.

- Prototyping & Small Batch: Quick response to small batch orders, shortening time to market.

- SMT Surface Mounting: High-precision automated mounting equipment.

- Wave Soldering: Highly efficient and stable soldering process.

- Functional Testing: Ensure PCBA functionality is complete and meets design requirements.

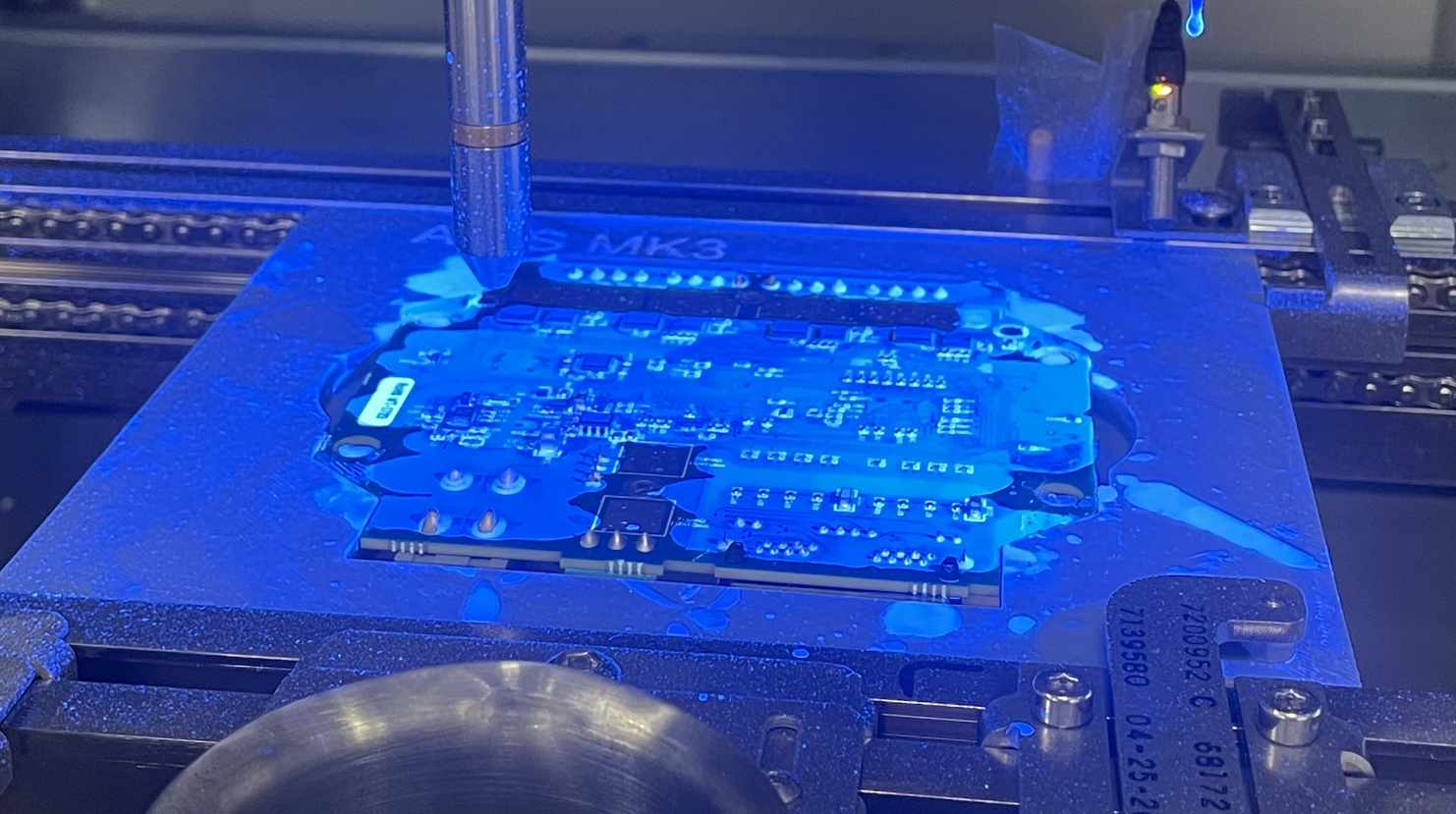

PCB Conformal Coating Process

PCB Conformal Coating protects electronic equipment from moisture, dust, external chemicals, and special use environments, ensuring its continuous stability. Angel Electronics, recognizing the increasingly widespread application of conformal coating, has added automated conformal coating lines using world-renowned PVA company's coating machines. This eliminates extensive masking and rework time, while also improving production capacity and stable quality, providing customers with competitive advantages. The main benefits of conformal coating are reflected in improving product reliability, extending service life, and enhancing environmental resistance.

Additionally, we can provide related coating processes:

- Potting Process: Achieve three-proof and product waterproofing IP-XX requirements.

- Underfill Process: Strengthen and enhance component solder joint strength, prevent vibration-induced cracks, and increase product reliability.

- LPM Low-Pressure Molding Process: Low-pressure injection molding in one piece, achieving three-proof and product waterproofing IP-XX requirements.