Complete Process Flow

Customer Sample Submission

Program Development

Preprocessing

Actual Board Coating

Curing Process

QC Inspection

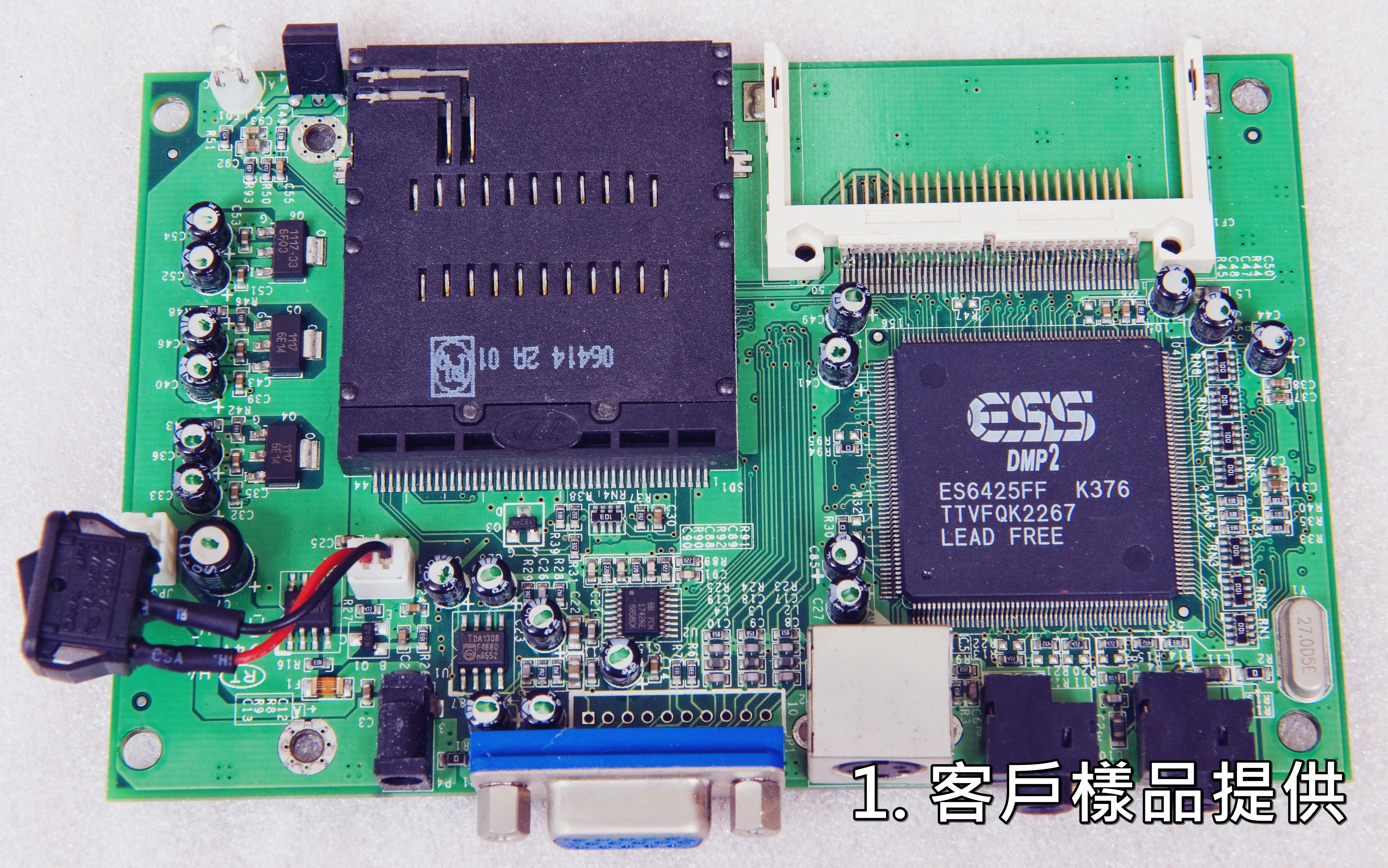

Step 1: Customer Sample Submission

Receive customer-provided PCB samples for initial evaluation and analysis

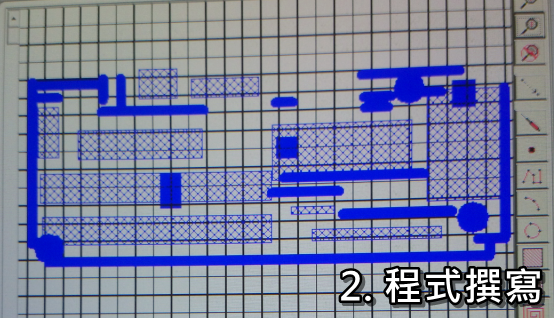

Step 2: Program Development

Develop coating programs based on product needs, setting coating paths and parameters

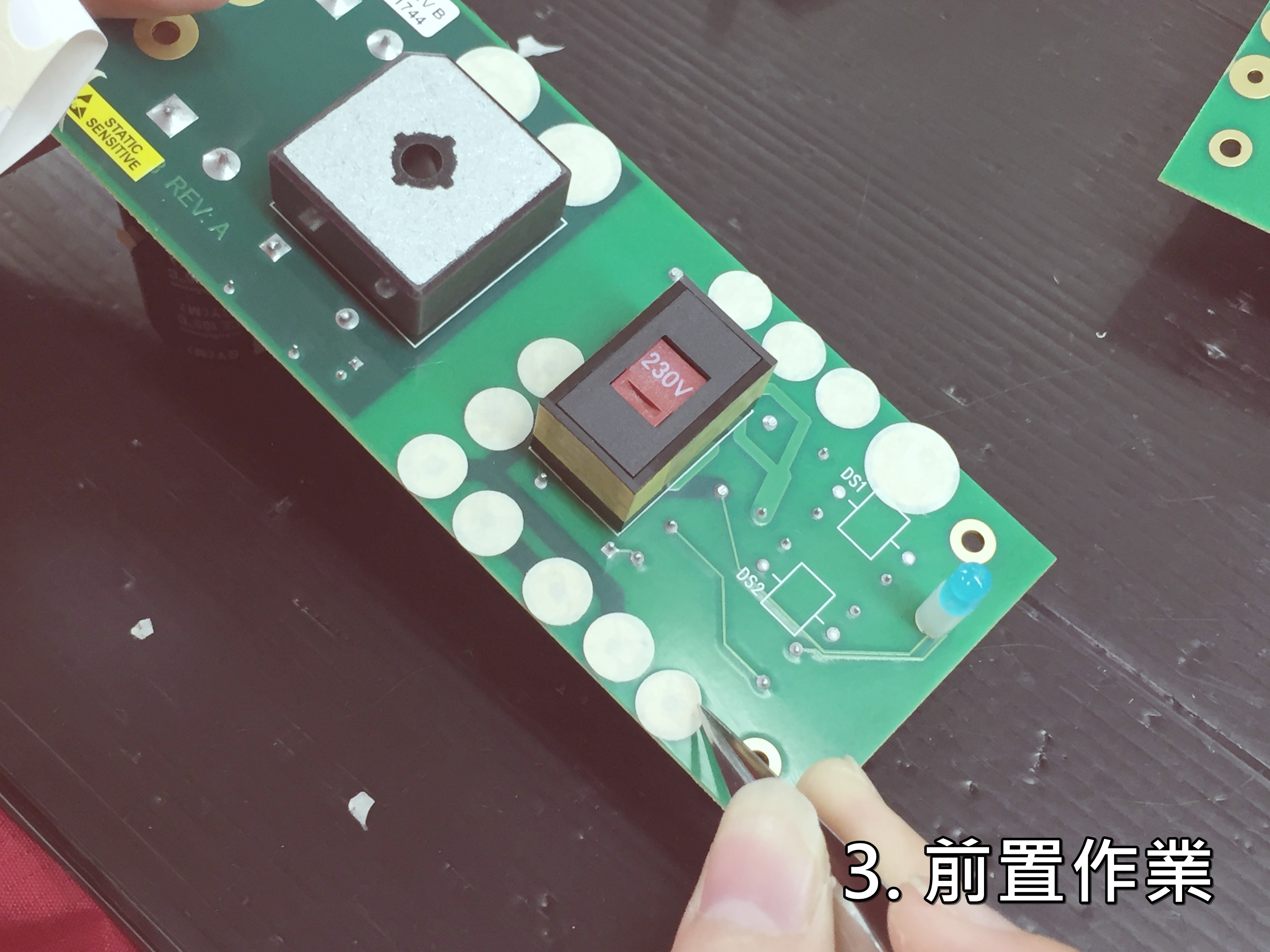

Step 3: Preprocessing

Clean PCB surfaces, mask areas not requiring coating, and prepare for coating

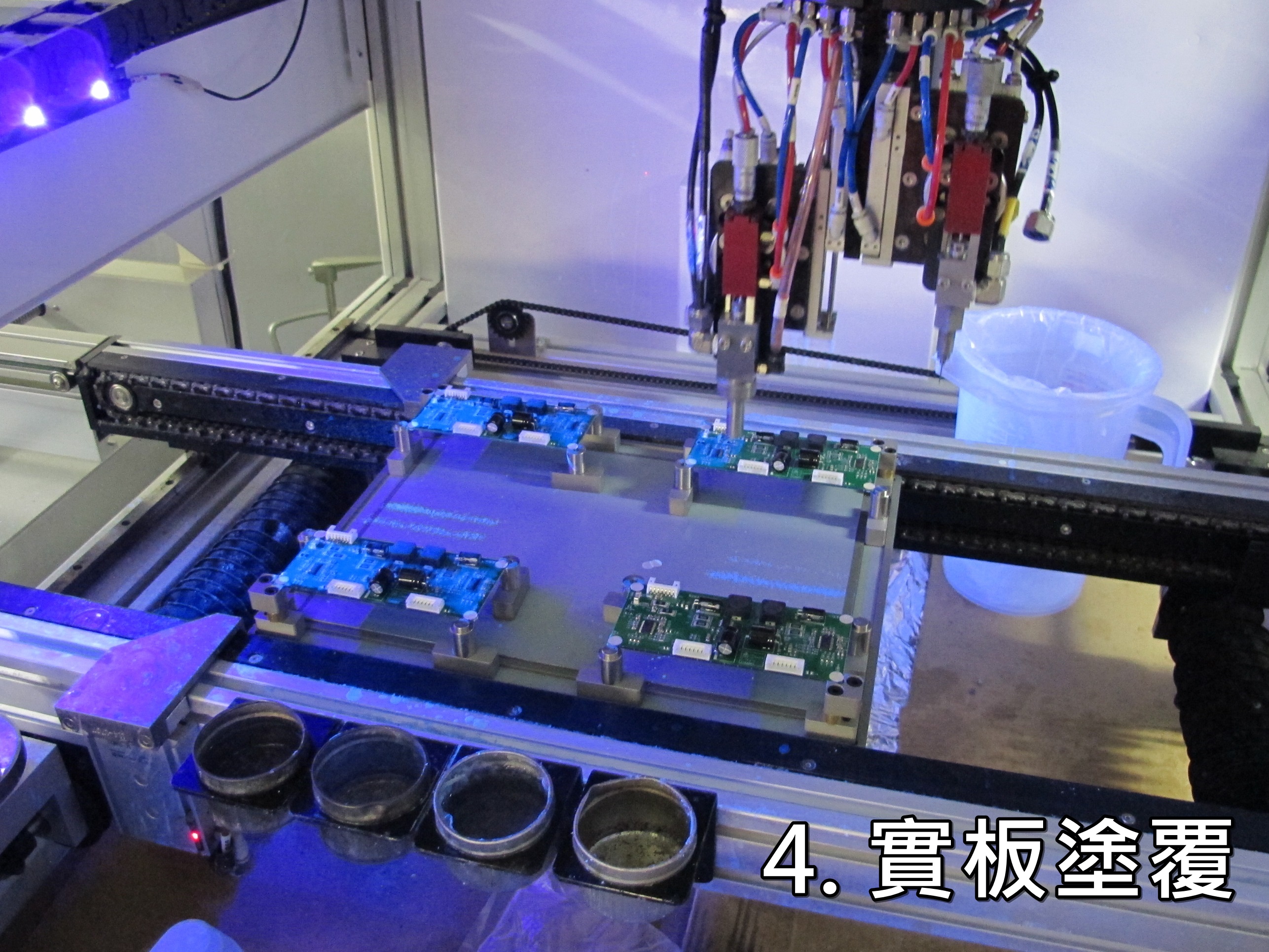

Step 4: Actual Board Coating

Use automated coating equipment for precise coating, ensuring uniform coverage

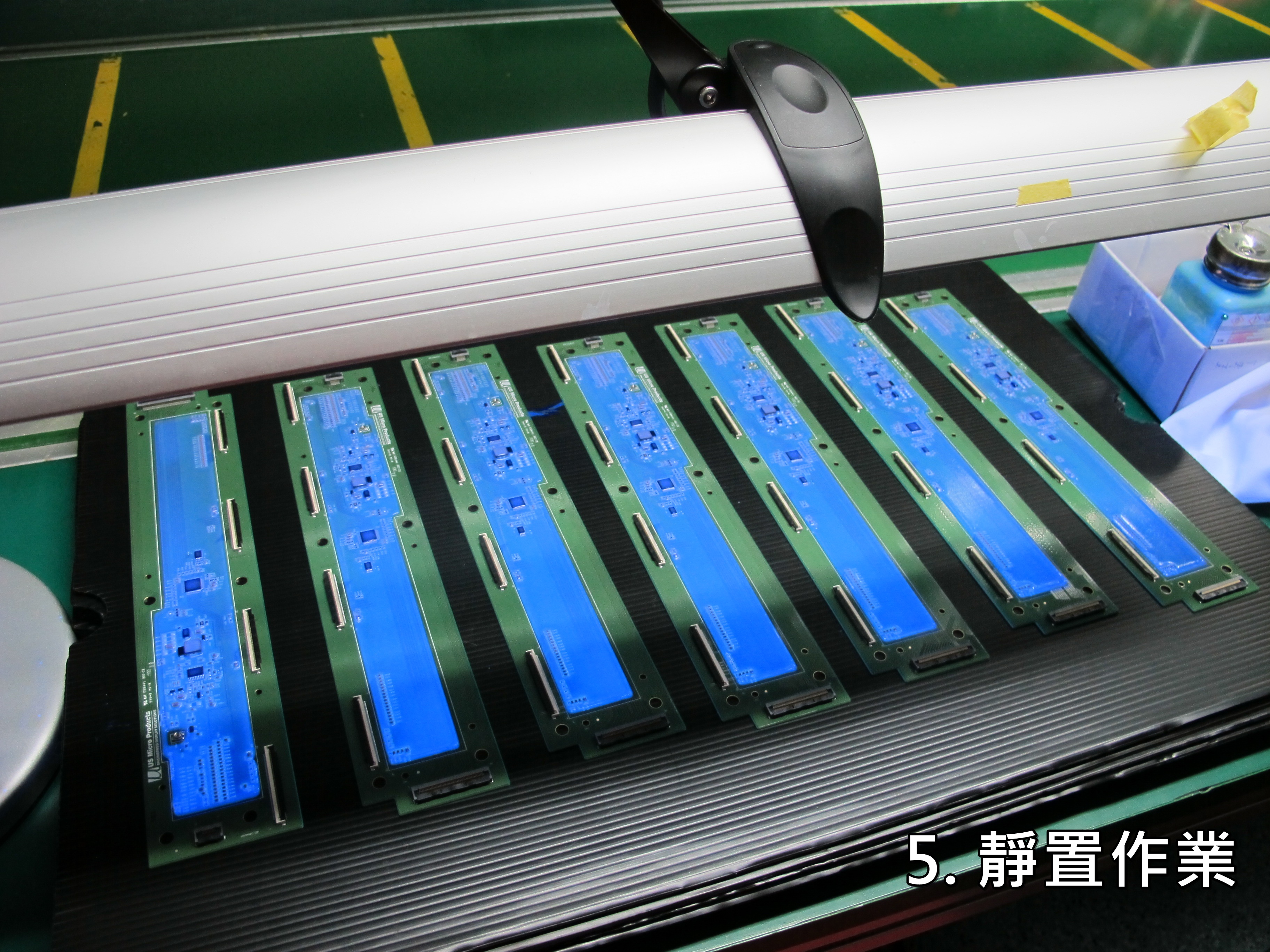

Step 5: Curing Process

Perform curing to fully harden the conformal coating, forming a protective layer

Step 6: QC Inspection

Conduct quality inspections to verify coating thickness, uniformity, and coverage meet standards